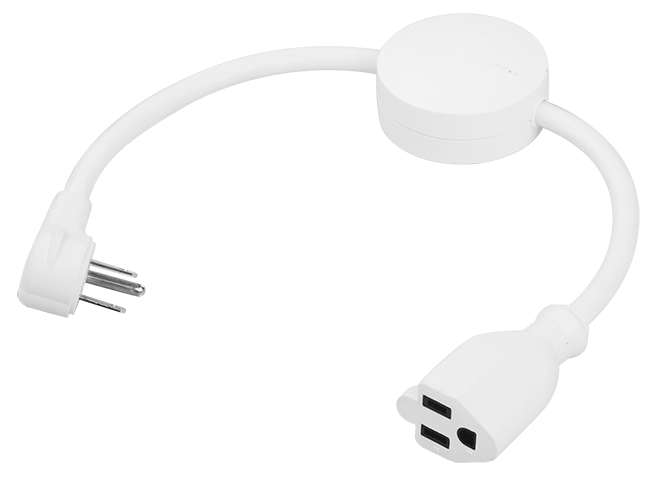

24/7 Automatic Monitoring and Rebooting

Ensure seamless internet connections and optimal speeds at all times with the ConnectSense Router Rebooter.

We're having difficulties processing online orders. Please contact us if you have troubles placing an order.

Webinar : 3/27 @ 11:30 AM ET - Enhancing Workplace Safety with Environmental Monitoring

Register Now

Grid Connect can customize or produce a product based on our technology that fits your requirements.

Quickly and effectively implement your partial or complete, networking or embedded product.

Grid Connect can customize or produce a product based on our technology that fits your requirements.

Quickly and effectively implement your partial or complete, networking or embedded product.

Ensure seamless internet connections and optimal speeds at all times with the ConnectSense Router Rebooter.

Automatic Reboots

Real-time outage correction monitors your internet connection with routine pings to limit downtime.

Scheduled Reboots

Maintain reliable internet speeds and prevent dropped devices with daily, scheduled reboots.

Remote Reboots

Control from anywhere, anytime a slow or downed connection happens with the iOS or Android app.

Perfect for:

The ConnectSense Internet Rebooter allows for 24/7 monitoring and control of your internet connection.

Looking for Help?

If you're looking for help with ConnectSense products, including Smart Outlet and EZ Lamp Controller, check out our help center below.

Sorry we were unable to add this item to your cart at this time.

Please try again and contact us if this problem persists. We recommend you reload this page.

Your cart qualifies for free shipping

This product has been added to your cart more than once. Edit your cart if this was a mistake.

Variant:

SKU:

Quantity:

Cart Subtotal ()

Taxes calculated at checkout

View Cart